Produits phares

Exceptional Barite Processing Methods and Machines

Apr 15, 2022The commonly used barite flotation methods include positive flotation and reverse flotation. The purpose of the latter is to remove alkali metal sulfides. The flotation machine is widely

Contact

Barite Processing Methods and Machines,Barite flotation and

Jun 20, 2022The beneficiation methods of barite mainly include manual selection, gravity separation, magnetic separation and flotation. Among them, the beneficiation of barite ore associated with sulfide

Contact

Method of processing bariteBeneficiation process Gravity

The more common approach (and the bulk of the printed (digital) information) is on floating the barite while depressing the gangue. this is because barite is usually found with other oxides in particular

Contact

What is the Processing method of barite powder?

Feb 08, 2018General Requirements for Barite Flotation Process 1, grinding fineness: barite flotation generally require grinding fineness to 200 mesh ,85 to 90%, usually the first paragraph grinding,the...

Contact

Barite Processing Methods and Machines,Barite flotation and

Jun 20, 20221. Barite hand selection method. After the raw ore is mined, simple manual selection is a common beneficiation method for many small mines. Due to the high geological grade and stable quality of some mines, qualified barite products can be selected according to the difference in color and density between barite and associated minerals.

Contact

Barite Mineral, Barite Grinding Plant, Barite Mineral

Barite is fragile and like a big tube. The separation methods of Xinhai are generally gravity separation magnetic separation and flotation. 【Application】: The process of high brightness micro powder and superfine powder. High brightness micro powder

Contact

What is the Processing method of barite powder?

Feb 08, 2018Process flow Residual barite ore generally gravity separation method for sorting, that is, after washing, crushing, screening with jigging or other gravity separation method to select barite

Contact

CN102909119A Ultra-fine barite powder processing method

The invention discloses a ultra-fine barite powder processing method, which comprises the following steps of: 1, roughly crushing barite raw ore, and then crushing again; 2, washing, finely selecting, dehydrating and drying; 3, grinding to 325-600 meshes; 4, mixing water and barite powder according to a certain proportion to form pulp, adding a drug, and leading the pulp to enter a buffer

Contact

What are the barite beneficiation methods?

The main mineral processing methods currently used are shown in the table. Generally, the residual ore is easy to be selected. Therefore, the re-election method is preferred; the sedimentary ore and the hydrothermal ore associated with sulfide ore, fluorite, etc., in addition to re-election, flotation method; barite flotation Anionic collectors

Contact

Which Barite Grinding Mill Is Best for Your Barite Grinding Plant?

Jun 24, 2022Barite grinding is generally divided into four types, namely, coarse powder processing (≤20 mesh), fine powder processing (20 mesh-400 mesh), ultra-fine powder processing (400 mesh-1250 mesh), and micro powder processing (1250 mesh-3250 mesh). It can be seen that the fineness of barite powder is an important consideration in choosing a barite

Contact

Mineral Processing EPC — The Common Barite Flotation Processing

Apr 19, 2021The froth flotation method is the main barite processing method. According to the type of salt-associated minerals, the barite ore can be divided into two categories: barite-quartz-calcite type ore and barite-fluorite type ore. Due to the similar surface chemical properties and similar flotation behavior between barite ore and associated salt

Contact

barite lead processing methods georgia spxlearningcenter

Method of processing barite Beneficiation process . I'm working on beneficiation of barium sulfate from low grade barite ore 64.2 BaSO4 in presence of 28.01 SiO2 and 4.8 PbO. 4.8 PbO with 28 SiO2. We want to achieve min 4.2 S.G with less than 250 ppm Lead. OCMA Standard Does anyone have any experiences on such ore.

Contact

Experimental modeling for upgrading of brown barite ore by

Feb 12, 2018Various processing methods were used to upgrade Mehdiabad brown barite ore (SG: 4.065 g/cm 3) to meet the standard quality for use as a drilling mud agent (SG more than 4.2 g/cm 3). Mineralogical analysis indicated that the main gangue phases in the ore are iron oxides, and particles were liberated at − 200 µm.

Contact

Baryte Mining Process Equipment Flow Cases JXSC

What is Baryte. Baryte is a mineral consisting of barium sulfate (BaSO4). baryte is generally white or colorless and is the main source of barium. The barite group consists of baryte, celestine (strontium sulfate), anglesite (lead sulfate), and anhydrite (calcium sulfate). Baryte and celestine form a solid solution (Ba, Sr)SO4.

Contact

Quantifying 226Ra activity in a complex assemblage of 226Ra

The non-null pixels after this thresholding are attributed to barite. This method is applicable to barite minerals because of the difference in density with the other minerals in the assemblage. It is not as effective for differentiating ferrihydrite and montmorillonite. For natural or synthesized samples, post-processing is required to

Contact

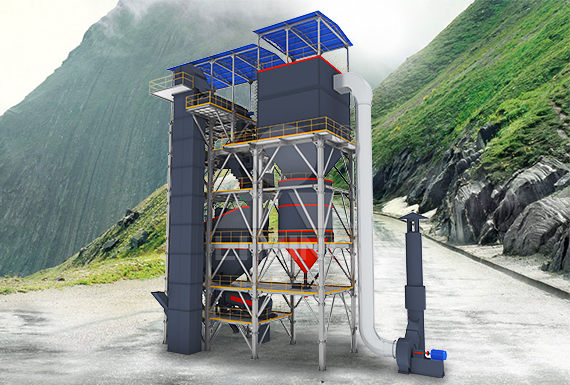

Baryte Processing Equipment, Process Flow, Cases JXSC Machine

Aug 26, 2019Baryte processing description from its geology mineral property to how to extract mineral from rock and placer deposit, related processing plant flow chart and layout design. Gold Mining Equipment Chat on WhatsApp

Contact

Ibarite mining in malaysia aquienergo

Mineral Notes: Barite • Snowden Mining and Production. The geometry and type of barite deposit affect mining economics and processing complexity. Vein deposits have complex geometry and may often be extracted from surface or underground as a co-product of metals mining. with consideration of mining methods and exploration, and

Contact

Subtask 1.23 Mercury Removal from Barite the Oil Industry

Sep 01, 2008The objective of this project was to demonstrate two mercury removal techniques for high-mercury barite sources. Two barite samples of unique origins underwent processing to reduce mercury to required levels. The chemical treatment with dilute acid removed a portion of the mercury in both barite samples. The desired concentration of 1 mg/kg was

Contact

What is the Processing method of barite powder?

Feb 08, 2018Process flow Residual barite ore generally gravity separation method for sorting, that is, after washing, crushing, screening with jigging or other gravity separation method to select barite

Contact

Barite Mineral, Barite Grinding Plant, Barite Mineral

Barite is fragile and like a big tube. The separation methods of Xinhai are generally gravity separation magnetic separation and flotation. 【Application】: The process of high brightness micro powder and superfine powder. High brightness micro powder

Contact

Baryte Processing Equipment, Process Flow, Cases

Aug 26, 2019Baryte processing description from its geology mineral property to how to extract mineral from rock and placer deposit, related processing plant flow chart and layout design. Gold Mining Equipment Chat on WhatsApp

Contact

barite processing method

Barite mineral processing methods According to the ore properties, mine scale and use of different, there are gravity separation and flotation. Read More. Processing Method of Barite-Bmschem. High whiteness fine barite powder is made by crushing, washing, whitening barite ore. Make use of barite to produce barium products: barium chloride

Contact

barite processing method alrom.fr

barite processing methods maijerinterieurtimmerwerknl. Barite powder grinding processing method and processing plant Barite Use Barite is a mineral consisting of barium sulfate The baryte group consists of baryte, celestine, anglesite and anhydrite Baryte itself is generally white or colorless, and is the main source of barium.

Contact

Baryte Mining Process Equipment Flow Cases JXSC

What is Baryte. Baryte is a mineral consisting of barium sulfate (BaSO4). baryte is generally white or colorless and is the main source of barium. The barite group consists of baryte, celestine (strontium sulfate), anglesite (lead sulfate), and anhydrite (calcium sulfate). Baryte and celestine form a solid solution (Ba, Sr)SO4.

Contact

Which Barite Grinding Mill Is Best for Your Barite Grinding Plant?

Jun 24, 2022Barite grinding is generally divided into four types, namely, coarse powder processing (≤20 mesh), fine powder processing (20 mesh-400 mesh), ultra-fine powder processing (400 mesh-1250 mesh), and micro powder processing (1250 mesh-3250 mesh). It can be seen that the fineness of barite powder is an important consideration in choosing a barite

Contact

Barite powder grinding processing method and

Barite powder grinding processing method and processing plant Barite Use Barite is a mineral consisting of barium sulfate. The baryte group consists of baryte,

Contact

Quantifying 226Ra activity in a complex assemblage of 226Ra

The non-null pixels after this thresholding are attributed to barite. This method is applicable to barite minerals because of the difference in density with the other minerals in the assemblage. It is not as effective for differentiating ferrihydrite and montmorillonite. For natural or synthesized samples, post-processing is required to

Contact

BENEFICIATION METHODS OF BARITE ORE IN ALGERIA

beneficia tion methods of barite ore in algeria T oufik Batouche 1,Abdel alli Bouzenzena 1,Ali Messai 2 1 Laboratory of Mines, mining institute, University of Larbi T ebessi, T ebessa, Algeria

Contact

Barite Mineral, Barite Grinding Plant, Barite Mineral

Barite Mineral Processing 【Introduction】: Barite is fragile and like a big tube. The separation methods of Xinhai are generally gravity separation magnetic separation and flotation. 【Application】: The process of high brightness micro powder and

Contact

method of processing barite atelieraline.fr

Feb 13 2017 nbsp 0183 32 Barite mineral processing technology symposium by HOT Lantis Ip Feb 13 2017 Barite mineral processing methods According to the processing of barite solidarite atakora org Feb 13 2017 Barite mineral processing methods According to the ore properties mine scale and use of different there are gravity separation and

Contact

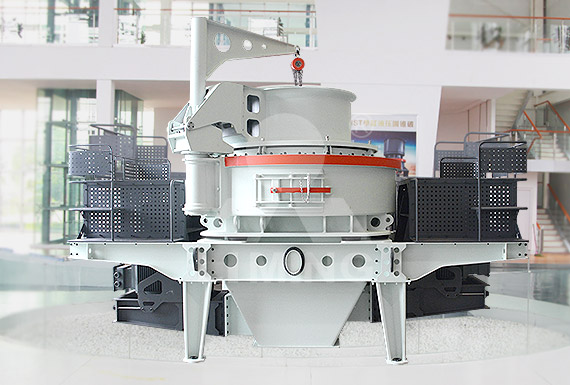

barite processing methods TIANCHANG Jaw Crusher

> barite processing methods; manufactured concrete sand. Manufactured Sand The MasterbuilderAug 12, 2015 River sand is a widely used construction material all over the world, especially in the production of concrete, cement-sand mortar and concrete North America''s Largest Concrete Producers Concrete Producer Aug 18, 2011 Manufacturer and

Contact

US6892814B2 Cement compositions containing coarse barite,

Cement comprising barite, a process for preparing such cement, and methods of cementing in a subterranean formation or well bore using such cement are provided. The cement is prepared by introducing coarse barite to the cement, the course barite comprising particles having a particle size primarily greater than about 125 microns.

Contact