Produits phares

Graphite ore flotation processing flow chart

The flotation of graphite ore is generally carried out by positive flotation followed by reverse flotation of the flotation concentrate. A higher grade graphite concentrate can be obtained by flotation. Flotation graphite concentrate grades can usually reach

Contact

Graphite ore flotation process introduction--CFCCARBON LTD

Flake graphite ore is characterized by scaly or leaf-like graphite, ore grade is not high, generally 3% to 5%, the maximum not more than 20% to 25%. This type of graphite floatability is good, the

Contact

Graphite Flotation Metal and Metallurgy engineering Eng-Tips

Jan 06, 2010The primary graphite formed during solidification is large and tends to float upwards due to lower density. The remaining liquid metal is then lowered in carbon content. Machining of such

Contact

Graphite By Froth Flotation Pure Line

graphite ore flotation process is an efficient graphite ore deep processing technology it can greatly increase the application of graphite ore area selected graphite ore concentrate can meet the diverse

Contact

Graphite ore flotation process introduction--CFCCARBON LTD

Flake graphite ore is characterized by scaly or leaf-like graphite, ore grade is not high, generally 3% to 5%, the maximum not more than 20% to 25%. This type of graphite floatability is good, the flotation, the grade up to 90% or more, so the ore grade 2% to 3% can be mined. Flake graphite performance, generally used in the manufacture of

Contact

flotation process for graphite

Graphite Flotation Process, Ore Beneficiation Equipment. Overview of Graphite Flotation Process. Graphite Ore. Graphite ore is one of four forms of crystalline carbon; the others are carbon nanotubes, diamonds, and fullerenes. Graphite occurs naturally in metamorphic rocks, such as gneiss, marble, and schist. It is a soft mineral also known by

Contact

Graphite Flotation Metal and Metallurgy engineering Eng-Tips

Jan 06, 2010Graphite flotation does not effect tensile poperties. It can reduce fatigue resistance marginally but i doubt it would cause a failure there maybe other factors that have caused this. If it has then your design criteria is too tight. This should be reviewed and fully investigated and understood. The main problem with graphite flotation is a

Contact

FR668938A Graphite flotation apparatus Google Patents

FR668938A FR668938DA FR668938A FR 668938 A FR668938 A FR 668938A FR 668938D A FR668938D A FR 668938DA FR 668938 A FR668938 A FR 668938A Authority FR France Prior art keywords graphite flotation flotation graphite Prior art date 1928-03-31 Legal status (The legal status is an assumption and is not a legal conclusion.

Contact

Technical Report: The occurrence of graphite flotation in a

Graphite flotation was observed to occur to an extent that depends on the carbon equivalent (C.E.) and casting modulus. In the present casting, graphite flotation occurred when the C.E. exceeded 4.42. Graphite particle clustering and graphite morphology degeneration into exploded nodules and compacted flake form was observed in the flotation zone.

Contact

Prevention of graphite floatation defects in iron castings

Precautions: (1) Strict control of carbon equivalent is the fundamental way to solve the problem of graphite floating. In general, carbon equivalent is controlled at 4.3% 4.7%. Thin and small parts are higher than the upper limit, thick and large parts are lower than the lower limit. (2) Speed up the cooling speed of the casting and place

Contact

Graphite flotation in ductile iron castings Free Online Library

Nov 01, 1990The graphite content is significantly higher in the float regions. Except when amounts of flotation or section sizes are small, the band has a carbon content of just over 5% and the area of the cross section occupied by graphite is just over 20%. As flotation becomes more severe, the extent of the affected zone increases. Graphite Appearance, Form

Contact

Floating defect of graphite in ductile iron casting

As a result, the surface quality and mechanical properties of castings are deteriorated. The floating of graphite is related to the carbon equivalent of the molten iron, the geometry of the casting and the cooling rate. In addition, it may also be related to the nucleation degree of the molten iron. The effect of cooling rate is more obvious.

Contact

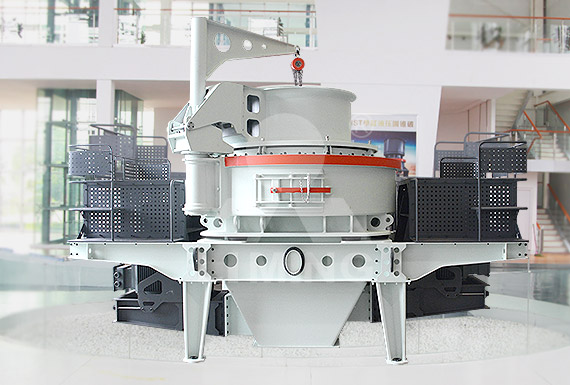

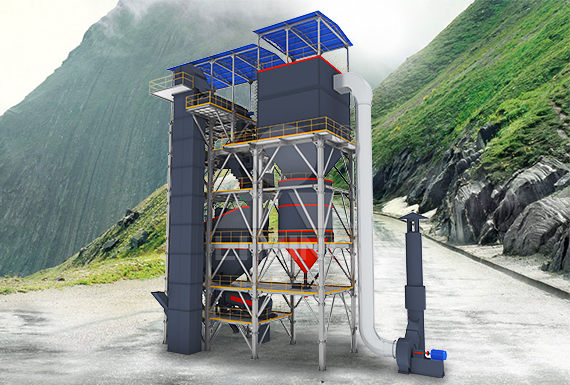

Graphite mineral processing flowsheet Jinpeng Mining

Graphite beneficiation method include flotation, electrostatic separation, gravity separation, etc. Flotation is the most widely used process. Graphite mineral processing are mainly suitable for all kinds of graphite with different crystal habit and graphite accompany with mica, etc silicate minerals or pyrite. Beneficiation method: flotation, electrostatic separation, gravity separation, etc

Contact

Graphite Wikipedia

Graphite (/ ˈ ɡ r æ f aɪ t /) is a crystalline form of the element carbon.It consists of stacked layers of graphene.Graphite occurs naturally and is the most stable form of carbon under standard conditions.Synthetic and natural graphite are consumed on large scale (300 kton/y ea, in 1989) for uses in pencils, lubricants, and electrodes.Under high pressures and temperatures it converts to

Contact

Flotation of spherodized graphite from spent Lithium Ion

Nov 14, 2019Flotation is a suitable process for recovering graphite, but challenging due to the fine particles. The present stone describes the positive effect of attritioning pre-treatment on spheroidized

Contact

Graphite Processing,Extraction,Crushing&Grinding Plant Design

Expandable / expanded graphite making. Stage grinding-flotation process. It is necessary to undertake the lab test or even pilot test for determining primary flake size and liberation size, improving the TGC grade as high as possible, meanwhile to find the suitable grinding-flotation way to reserve the big flake size graphite.

Contact

How to know natural graphite?-Company News-News-graphite

Jul 01, 2022Graphite (/ˈɡræfaɪt/) is a crystalline form of the element carbon. It consists of stacked layers of graphene. Graphite occurs naturally and is the most stable form of carbon under standard conditions. Natural graphite is a refractory material with a high melting point of 3650 °C, and it is a good conductor of heat and electricity.

Contact

Flotation Mineral ProcessingMetallurgy

Jan 11, 2016The FLOTATION PROCESS is one of the commonest methods of extracting the valuable minerals from certain classes of ores, and it is generally more efficient as regards the recovery of the minerals than any other process applicable to the treatment of similar types of ores. The metallic contents of the minerals are recovered from the concentrates in a subsequent series of metallurgical operations

Contact

flotation process for graphite

Graphite Flotation Process, Ore Beneficiation Equipment. Overview of Graphite Flotation Process. Graphite Ore. Graphite ore is one of four forms of crystalline carbon; the others are carbon nanotubes, diamonds, and fullerenes. Graphite occurs naturally in metamorphic rocks, such as gneiss, marble, and schist. It is a soft mineral also known by

Contact

Graphite By Froth Flotation Pure Line

Graphite Wikipedia. The beginnings of the revolutionary froth flotation process are associated with graphite mining Included in the EMJ article on the Dixon Crucible Company is a sketch of the floating tanks used in the ageold process of extracting graphite Because graphite is so light the mix of graphite and waste was sent through a final series of water tanks where a cleaner graphite floated

Contact

graphite flotation SRE Machineries

Graphite floatation This is caused when large low density graphite nodules are formed during the solidification of thick section or otherwise slow cooling castings The nodules being of a lower density than the matrix tend to float towards the surface of the casting and thus can have a negative. .

Contact

Graphite Flotation Plant,Graphite Mining Processing Line

Location: China Mineral Ore Type: Graphite ore Raw Ore Grade: 5.8% above Final Product: 92% concentrate Recovery Rate: 88% Plant Capacity: 1500 t/d Technological Process: crushingsieving + ball mill stage grindingclassification + stage flotation + thickeningfiltering Normally flotation is applied for graphite processing, but the big flake should be preserved.

Contact

Technical Report: The occurrence of graphite flotation in a

Graphite flotation was observed to occur to an extent that depends on the carbon equivalent (C.E.) and casting modulus. In the present casting, graphite flotation occurred when the C.E. exceeded 4.42. Graphite particle clustering and graphite morphology degeneration into exploded nodules and compacted flake form was observed in the flotation zone.

Contact

Prevention of graphite floatation defects in iron castings

Precautions: (1) Strict control of carbon equivalent is the fundamental way to solve the problem of graphite floating. In general, carbon equivalent is controlled at 4.3% 4.7%. Thin and small parts are higher than the upper limit, thick and large parts are lower than the lower limit. (2) Speed up the cooling speed of the casting and place

Contact

Graphite Wikipedia

Graphite (/ ˈ ɡ r æ f aɪ t /) is a crystalline form of the element carbon.It consists of stacked layers of graphene.Graphite occurs naturally and is the most stable form of carbon under standard conditions.Synthetic and natural graphite are consumed on large scale (300 kton/y ea, in 1989) for uses in pencils, lubricants, and electrodes.Under high pressures and temperatures it converts to

Contact

FR668938A Appareil de flottation de graphite Google Patents

FR668938A FR668938DA FR668938A FR 668938 A FR668938 A FR 668938A FR 668938D A FR668938D A FR 668938DA FR 668938 A FR668938 A FR 668938A Authority FR France Prior art keywords graphite flotation flotation graphite Prior art date 1928-03-31 Legal status (The legal status is an assumption and is not a legal conclusion.

Contact

How to know natural graphite?-Company News-News-graphite

Jul 01, 2022Graphite (/ˈɡræfaɪt/) is a crystalline form of the element carbon. It consists of stacked layers of graphene. Graphite occurs naturally and is the most stable form of carbon under standard conditions. Natural graphite is a refractory material with a high melting point of 3650 °C, and it is a good conductor of heat and electricity.

Contact

How Metallurgical Testing For Graphite Is Done Sepro Labs

Oct 07, 2019There are a few different ways to perform metallurgical testing for graphite depending on what you’re looking to achieve. We can provide tests that involve flotation, gravity concentration, leaching, scrubber testing, flake size characterization, and assaying for graphite. The sample requirements vary depending on which testing procedure is

Contact

(PDF) THE BENEFICIATION OF GRAPHITE BY FLOTATION USING

THE BENEFICIATION OF GRAPHITE BY FLOTATION USING A LOCALLY SOURCED COLLECTOR SOYBEANS OIL NUHU, STEVEN KUBA. S. (SEDInst) Related Papers. Handbook of Flotation Reagents Chemistry, Theory and Practice: Flotation of Sulfide Ores. By luis araya. FLOTATION ROUTES FOR A PHOSPHATE ORE BEARING SILICATE-CARBONATE GANGUE.

Contact

Graphite Beneficiation Process JXSC Machine

Dec 20, 2018The scale graphite flotation process is generally a closed-circuit process of multi-stage grinding, multi-stage sorting, and medium-mine order (or centralized) return. There are three forms of multi-stage processes, namely re-grinding of concentrates, re-grinding of mines and re-grinding of tailings. Crystalline graphite is mostly used in the

Contact

A Review of Graphite Beneficiation Techniques Request PDF

Graphite ore is mostly beneficiated using flotation separation techniques. The increasing demand for high-grade graphite products with up to 99.99% carbon has resulted in the development of

Contact

Procédé projetlacgueret Mason Graphite

Quels sont les réactifs utilisés dans le processus de flottation? Cette huile reste sur le graphite et, quand on fait le séchage, elle brule et s’évapore. On utilise aussi un moussant pour retenir le graphite à la surface, soit un alcool qui se dégrade très rapidement, en quelques heures. Enfin, on

Contact